- This topic is empty.

-

AuthorPosts

-

16/05/2025 at 13:58 #82376

In the field of industrial transmission, magnetic coupler and hydraulic coupler are highly regarded key components, they shoulder the power from the power source accurately and efficiently transmitted to the load equipment important mission. However, after a comprehensive consideration of various aspects and practical application comparison, it is not difficult to find that the magnetic coupler transmission mode in many key indicators show significantly better than the characteristics of the hydraulic coupler, the following let's explore a little more in-depth.

Advantages based on the working principle

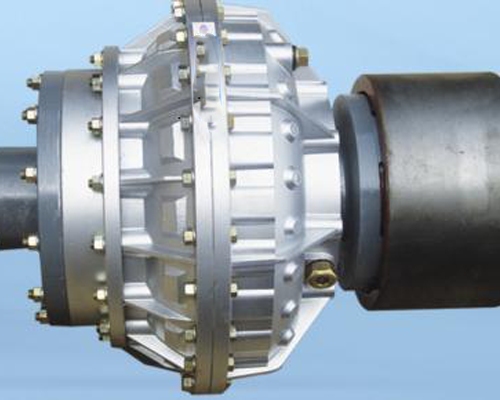

The working principle of the magnetic coupler is very innovative and unique. It mainly relies on the magnetic field to realize the power transmission, and its structure contains key parts such as the active end, the driven end and the magnet group. When the motor drives the active end to start rotating, the powerful magnetic field will cross the gap between the active end and the slave end, like an invisible but powerful “hand”, firmly “holding” the slave end, making it rotate synchronously, and then complete the transmission of power. This contactless transmission mode avoids the wear and tear problem caused by physical contact from the root, and lays a good foundation for the long-term stable operation of the equipment.

On the contrary, hydraulic coupler, it is with the help of working fluid in the pump wheel and turbine flow between the transmission of power. When the motor drives the pump wheel to rotate, driving the working fluid to impact the turbine, so that the turbine rotates, thus driving the load work. But this relies on the liquid medium transmission, there is inevitably a liquid leakage, component wear and energy loss and other hidden dangers, after all, the liquid in a long period of time in the flow and impact process, the internal components will cause a certain degree of erosion, and sealing link once the problem occurs, it is easy to lead to leakage and other failures.

Excellence in performance

Starting performance

The magnetic coupler has excellent flexible starting ability, which enables the motor to avoid a sharp rise in current at the starting moment and realize a smooth and steady starting process. This is like installing a “buffer” to the starting process of the motor, which greatly reduces the starting burden of the motor, not only prolonging the service life of the motor, but also making the entire transmission system more stable and reliable during the starting phase.

In contrast, although the hydraulic coupler can also play a certain buffer role in the startup, but due to the inertia of the liquid flow and its internal structural characteristics, the startup process is relatively less precise, and in some industrial scenarios that require high startup accuracy, it is slightly inferior.

Energy saving and efficiency

Magnetic coupler in the operation process, due to the contactless transmission reduces the additional friction loss, its transmission efficiency can usually reach a high level, generally in 97% – 99%, the total energy efficiency of the system can also be maintained at 94% – 97% or so, which means that it can transfer the energy of the power source to the load side in a very high proportion, minimize the waste of energy, for the enterprise to save a considerable amount of operating costs.

The hydraulic coupler due to the working fluid in the transmission of power in the process of internal friction, liquid splash and other energy loss, its transmission efficiency is generally only 83% – 87%, the total energy efficiency of the system is only 80% – 85% or so, in the energy-saving aspects of the obvious backwardness of the magnetic coupler, the long-term use of the cumulative gap in the cost of energy should not be underestimated.

Overload protection capability

The magnetic coupler has a fast and intelligent response mechanism in the face of overload conditions. Once the overload is detected, it can quickly release the coupling state, effectively blocking the damage caused by the overload to the motor, the load and itself, like equipping the whole transmission system with a “security guard” who is always on the alert to protect the safety and integrity of the equipment.

Fluid coupler in the overload, often by spraying oil pressure relief and other ways to protect themselves, but such a way is not only easy to cause environmental pollution, but also may lead to the internal components are contaminated, and subsequently need to spend a lot of time and energy to clean up, repair and replace parts, and can not be as accurate as the magnetic coupler to protect the motor and load, easy to make other equipment is also implicated in the increase in the risk of failure.

Installation and maintenance highlights the convenience and ease of mind

Magnetic coupler structure is relatively compact, the installation does not require complicated ancillary equipment, and the installation of the active end and the follower end of the eccentricity of the situation has a greater degree of tolerance, the installer can easily complete the installation and dismantling work. More importantly, it is a maintenance-free mechanical products, do not need to lubricate, replace wear parts and other routine maintenance operations, greatly reducing the cost of operation and maintenance of equipment and workload, but also reduces the maintenance of the equipment downtime, so that the production can be sustained and stable.

The installation process of the hydraulic coupler is relatively cumbersome, requiring the use of flexible couplings to assist, and its volume is large, installed on the motor shaft may also affect the service life of the motor bearings. In daily use, it must regularly check and maintain its sealing condition, and constantly fill or replace the hydraulic transmission oil, which undoubtedly increases the enterprise's manpower and material investment, and once the maintenance is not timely, it is easy to cause various failures, affecting normal production.

Applicable scene to expand the more advantageous

With the development of modern industry in the direction of refinement, intelligence and environmental protection, the requirements for transmission equipment are getting higher and higher. Magnetic coupler by virtue of its non-contact, energy efficient, low vibration, maintenance-free and many other advantages, in the chemical industry, medicine, food processing and other strict environmental requirements, the need for precision operation of the industry shine, but also well adapted to such as the belt conveyor and other need for flexible start, smooth operation and reliable overload protection of the equipment, the scope of application continues to expand.

Although the hydraulic coupler in some heavy-duty transmission, the start of the smoothness of the higher requirements of the traditional heavy industry, such as mining, shipping and other industries have a certain place, but it is limited by the efficiency, environmental protection and maintenance and other aspects of the shortcomings of the new industrial sector to expand when faced with a number of constraints, the application of the scene is relatively more limited.

In summary, the magnetic coupler with its unique working principle, excellent performance, convenient installation and maintenance, as well as a wide range of applicable scenarios and other advantages, in comparison with the hydraulic coupler stood out. Of course, different industrial scenarios have different needs, hydraulic coupler also in specific areas to play its own value, but it is undeniable that the magnetic coupler transmission mode in more and more cases show more in line with the advantages of the modern industrial development trend, is gradually becoming a large number of enterprises in the choice of transmission equipment on the priority of the object of consideration.

http://www.magicmag-tech.com

SHANGHAI GAOLV E&M Technology Co.,Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.