- This topic is empty.

-

AuthorPosts

-

04/11/2025 at 09:47 #83520

Understanding the Precision Automobile Steering Gear

A precision automobile steering gear is a critical mechanical component within the steering system that directly influences vehicle handling, responsiveness, and driving safety. Unlike conventional gears used in industrial equipment, steering gears are engineered with exceptional accuracy to ensure smooth force transmission and precise steering angle control. The component’s performance determines how effectively a driver’s steering input is translated into wheel movement, making it a vital part of modern automotive design. In this blog post, Longruifa, as one of the high performance automotive gear manufacturers, will share the structural characteristics of precision automobile steering gear for sale, etc.

Structural Characteristics of Precision Steering Gear Components

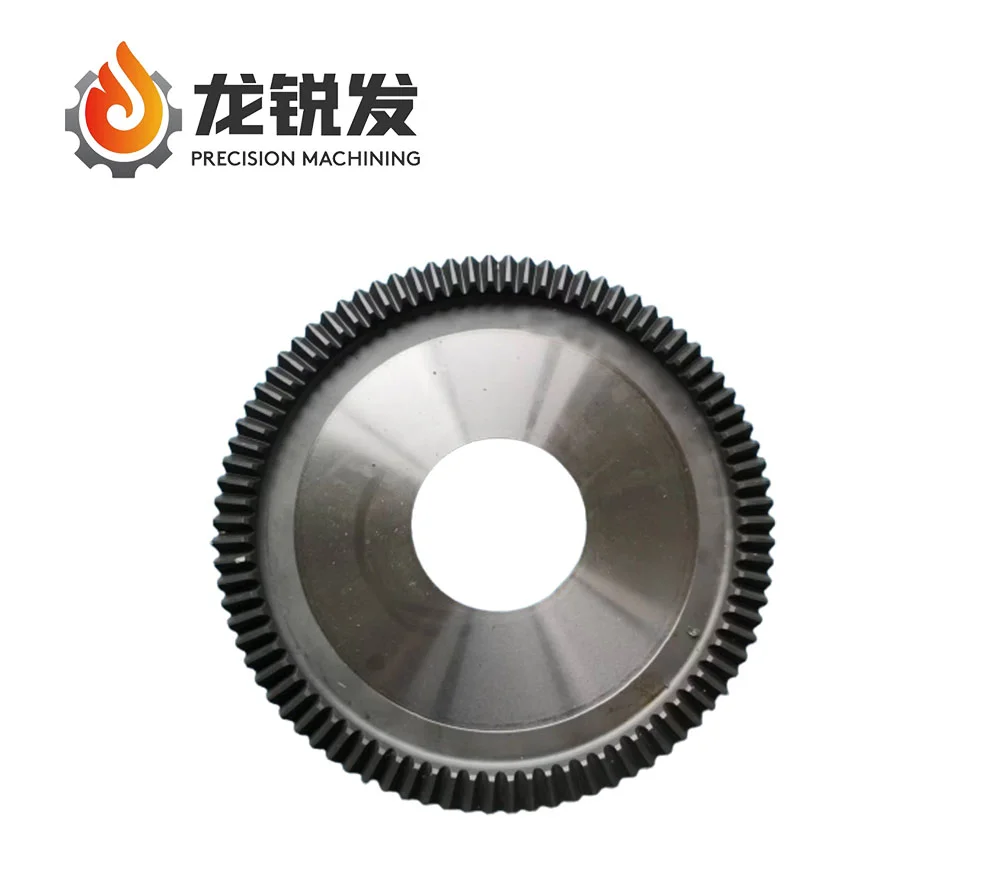

At its core, the automobile steering gear consists of a disc-shaped metal component with spiral teeth meticulously arranged along its edges. A central circular hole allows it to integrate seamlessly with other steering components.

Each tooth is machined with micro-level precision to ensure flawless meshing with the pinion or rack mechanism. This spiral gear structure provides gradual engagement, which reduces vibration and noise during steering.The material composition—typically high-strength alloy steel or hardened metal—enhances durability and wear resistance, ensuring the gear maintains its accuracy over years of use. The meticulous manufacturing process, involving precision grinding and surface treatment, contributes to consistent performance under varying loads and environmental conditions.

How Precision Steering Gear Improves Vehicle Control

The precision steering gear mechanism converts the driver’s rotational motion of the steering wheel into the linear or angular motion required to turn the vehicle’s wheels. When properly designed, this conversion process is highly responsive and balanced.

-

Force Transmission Efficiency: The spiral gear teeth ensure even load distribution across the contact area, minimizing mechanical losses.

-

Directional Stability: Accurate tooth alignment helps maintain consistent steering ratios, resulting in stable directional control at both low and high speeds.

-

Smooth Operation: Reduced backlash between gear teeth contributes to fluid steering response, enhancing comfort and confidence for the driver.

These functional advantages make precision steering gears indispensable in vehicles where high-performance handling and safety are paramount.

Integration of Precision Automobile Steering Gears in Modern Vehicles

The application of precision steering gears extends across a broad spectrum of vehicle types—from passenger cars to heavy-duty trucks and specialized machinery. In electric vehicles (EVs) and autonomous driving systems, steering gears play a crucial role in enabling electronic steering control modules to execute minute adjustments in real time.

Modern automotive engineering trends demand gears that can withstand high torque while maintaining micrometer-level accuracy. This has led to innovations such as electromechanical steering gear systems and variable-ratio gears, which optimize steering feel according to driving conditions.

The ability of precision steering gears to integrate seamlessly with sensors and control units further enhances vehicle dynamics, supporting features like lane-keeping assistance and adaptive steering.

Manufacturing Precision: From Gear Design to Assembly

The production of precision steering gears involves advanced engineering processes that guarantee structural integrity and performance reliability.

Key stages include:-

Material Selection: Choosing alloy steels with high fatigue strength and corrosion resistance.

-

CNC Machining: Utilizing computer numerical control systems to cut and shape teeth with sub-micron accuracy.

-

Heat Treatment: Hardening processes that enhance surface wear resistance without compromising core toughness.

-

Precision Grinding and Lapping: Refining tooth surfaces for optimal smoothness and noise reduction.

-

Quality Testing: Each gear undergoes strict dimensional and performance inspections to ensure compliance with automotive standards.

The combination of these techniques ensures that every precision automobile steering gear can endure mechanical stress and deliver consistent steering feedback.

Reliability and Durability in Automotive Steering Systems

A precision steering gear assembly must operate under challenging conditions, including variable loads, temperature changes, and continuous vibration. Therefore, reliability testing and durability assessments are essential.

Engineers simulate long-term wear and environmental exposure to evaluate:-

Gear tooth fatigue resistance

-

Lubrication retention and friction performance

-

Corrosion protection under humidity and temperature cycling

The outcome is a gear system that maintains its precise functionality throughout the vehicle’s lifespan, significantly reducing maintenance requirements and improving driver safety.

Advancing Vehicle Technology Through Steering Gear Innovation

The evolution of precision steering gear technology is closely tied to broader automotive innovation. With the rise of intelligent driving systems and electric power steering (EPS), gears are now designed to integrate electronic feedback mechanisms. These systems detect road resistance and adjust steering effort automatically, ensuring optimal handling across all driving scenarios.

Moreover, advancements in lightweight materials and additive manufacturing have allowed manufacturers to produce gears that balance strength with reduced weight, contributing to better fuel efficiency and environmental sustainability.

The ongoing development of digital twin simulation and AI-assisted manufacturing further refines gear performance prediction and customization, setting new standards for accuracy and reliability in the automotive sector.

Conclusion

The precision automobile steering gear embodies the intersection of mechanical mastery and technological innovation. From its spiral-tooth geometry to its integration into intelligent steering systems, every detail reflects the pursuit of superior control, comfort, and safety in modern vehicles.

As the automotive industry transitions toward electric and autonomous mobility, precision steering gears will continue to evolve—enabling vehicles to steer with human-like accuracy and mechanical consistency. This component, though small in appearance, remains one of the most sophisticated and indispensable parts of automotive engineering, driving the future of precision-controlled transportation.

http://www.lrfgears.com

Longruifa -

-

AuthorPosts

- You must be logged in to reply to this topic.