- This topic is empty.

-

AuthorPosts

-

08/09/2025 at 14:10 #83214

In the world of advanced manufacturing, where light transmission, clarity, and precision determine the performance of devices,optical adhesive is a critical yet often overlooked component. Whether it is a smartphone display, an automotive head-up display, a medical diagnostic device, or a fiber optic communication system, the correct choice of optical adhesive ensures optimal performance, durability, and user satisfaction. Unlike ordinary bonding agents, optical adhesives are engineered to maintain excellent transparency, resist yellowing, and minimize optical distortions. They must also balance mechanical strength with flexibility, survive harsh environmental conditions, and provide long-term reliability without compromising light pathways. This makes them indispensable in industries that depend on optical accuracy and stability.

What is an Optical Adhesive?

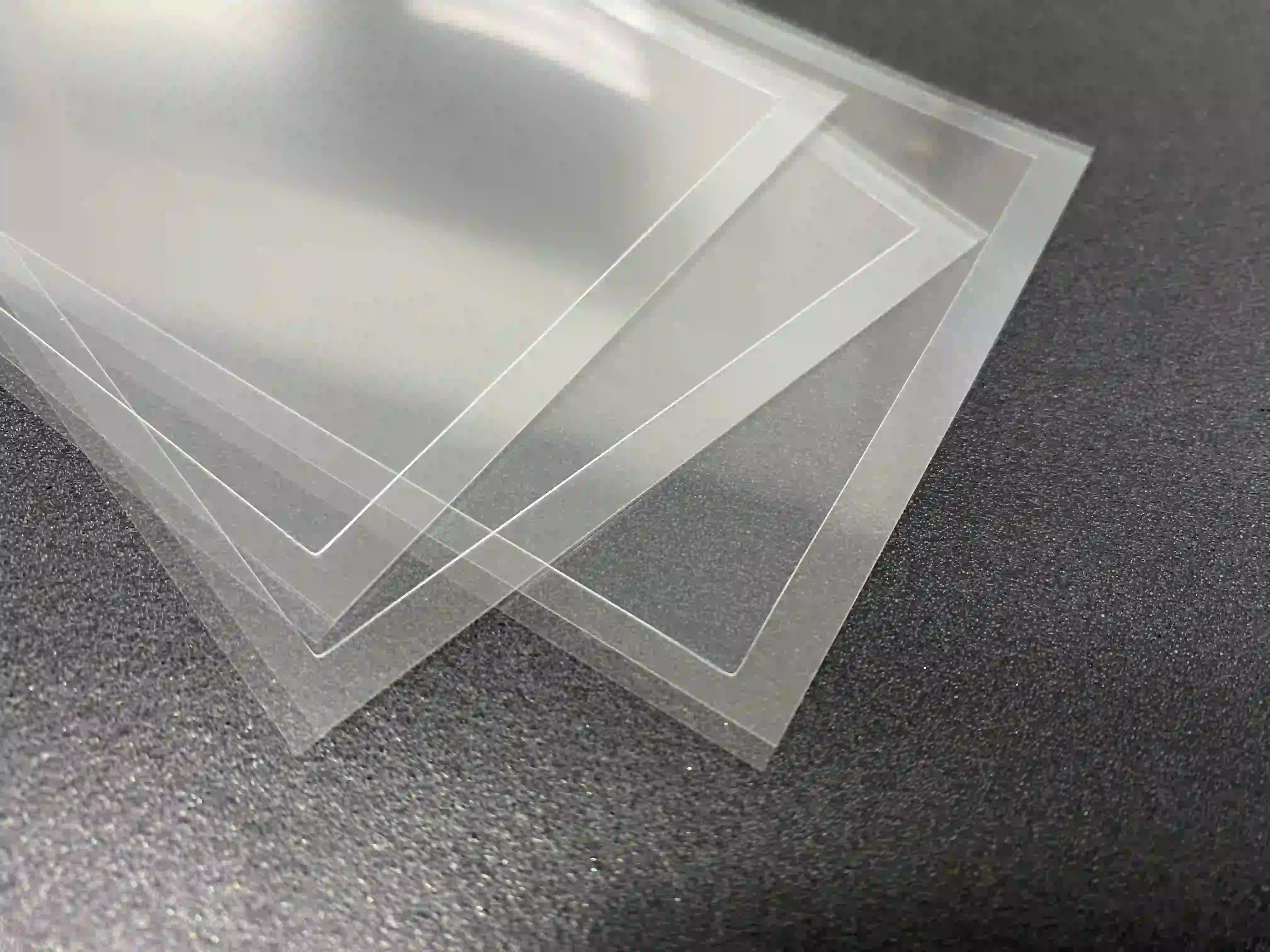

An optical adhesive is a specially formulated bonding material used to join optical components like glass, lenses, prisms, plastic substrates, displays, and fiber optics while maintaining their ability to transmit light without distortion.

The main difference between optical adhesives and traditional glues is their ability to remain clear, stable, and optically compatible with the materials they join. For instance, when bonding a glass lens to a plastic layer, the adhesive must match the refractive indices closely to minimize reflection. Furthermore, it should not yellow or degrade after years of exposure to UV light or fluctuating temperatures.

In high-tech industries, optical adhesive is not just a bonding layer; it is part of the optical system itself, directly influencing performance. Any deviation in clarity, shrinkage during curing, or misalignment could compromise product functionality. Therefore, engineers treat optical adhesive selection with the same importance as lens design or sensor calibration.

Applications of Optical Adhesive

The adaptability of optical adhesive has led to widespread adoption across industries, offering strong bonding, excellent transparency, and long-term durability. By minimizing air gaps and ensuring stable light transmission, it enhances performance in many demanding fields.

1. Consumer Electronics

In smartphones, tablets, and laptops, optical adhesive bonds the cover glass to LCD or OLED displays. This process not only improves sunlight readability but also enhances touch sensitivity and protects delicate screens from scratches and impacts. For wearable devices such as smartwatches or fitness trackers, the adhesive must combine transparency with flexibility, remaining lightweight while offering resistance to sweat, heat, and constant movement. The use of optical adhesive ensures that consumer electronics deliver crisp images, accurate touch response, and long-lasting durability.

2. Automotive Displays and Lighting

Modern vehicles rely on digital dashboards, infotainment systems, head-up displays (HUDs), and LED lighting. Optical adhesive plays a critical role by eliminating glare and reducing internal reflections, allowing drivers to clearly read displays even in bright sunlight. In addition, it provides long-term resistance against UV exposure and high temperatures inside cars. Because vehicles operate in high-vibration conditions, the vibration tolerance of optical adhesive ensures that displays and lighting components remain reliable, safe, and free from delamination throughout years of use.

3. Telecommunications and Fiber Optics

Fiber optic networks demand materials that support ultra-low signal loss. Optical adhesive is used to bond optical fibers within connectors, transceivers, and splitters. The right formulation prevents microbending losses, minimizes unwanted reflections, and guarantees stable signal transmission even under the stress of high-speed communication loads. In the telecommunications industry, where data integrity is essential, optical adhesive provides the secure bonding and optical clarity that keep global communication systems efficient and dependable.

4. Medical and Life Sciences

In diagnostic devices, endoscopes, imaging instruments, and laboratory microscopes, optical adhesive ensures accurate light transmission without distortion or contamination. Biocompatible grades are essential in medical applications where adhesives may come into contact with human tissue, fluids, or sterilization processes. By maintaining optical clarity and preventing microcracks or contamination, optical adhesive enables reliable performance in medical diagnostics, helping doctors and researchers achieve precise imaging and accurate results.

5. Aerospace and Defense

Aerospace and defense technologies place extreme demands on materials. Satellites, avionics systems, and laser targeting devices must operate in environments with vacuum, vibration, and temperature extremes. Optical adhesiveis designed to resist outgassing in space conditions while retaining high transparency and mechanical stability. Its ability to withstand radiation, shock, and long-term thermal cycling makes optical adhesive indispensable in space missions, defense sensors, and advanced military optics.

Optical Adhesive in Display Technology

Display performance is one of the most visible and critical applications of optical adhesive, as it directly impacts how users interact with devices.

-

Elimination of Air Gaps: By filling the microscopic gap between the cover glass and the display panel, optical adhesive improves brightness, contrast, and sharpness, leading to a clearer and more immersive viewing experience.

-

Sunlight Readability: The reduction of internal reflections ensures that displays remain highly visible even under direct sunlight, which is crucial for smartphones, ATMs, kiosks, and automotive dashboards.

-

Touch Responsiveness: With fewer barriers between glass and sensors, the optical adhesive enhances touch accuracy and responsiveness, making interactions smoother and more precise.

-

Durability: Strong bonding prevents delamination, cracking, and dust intrusion. This ensures that displays remain intact and functional even after long-term use or under mechanical stress.

-

Thin and Lightweight Designs: Optical adhesive allows manufacturers to create sleeker, thinner devices without sacrificing performance, meeting the growing consumer demand for portability and elegant design.

From consumer devices to industrial equipment, the integration of optical adhesive in display technology ensures that products deliver superior performance, durability, and user satisfaction.

The optical adhesive is far more than a bonding solution—it is an enabler of modern technology. By ensuring clarity, stability, and strength, it has become indispensable in electronics, automotive, telecommunications, medical, and aerospace sectors. For procurement managers, engineers, and manufacturers, selecting the right optical adhesive means balancing performance requirements with supplier reliability. When chosen correctly, it ensures longer product lifespans, improved customer experience, and optimized production efficiency. In an era where precision and performance define competitiveness, the optical adhesive stands as the invisible yet essential component powering innovation.

https://www.opticaladhesives.com/Optical-Adhesives

http://www.opticaladhesives.com

Suzhou PeiYang New Material Technology Co. Ltd -

-

AuthorPosts

- You must be logged in to reply to this topic.