- This topic is empty.

-

AuthorPosts

-

09/06/2025 at 16:40 #82561

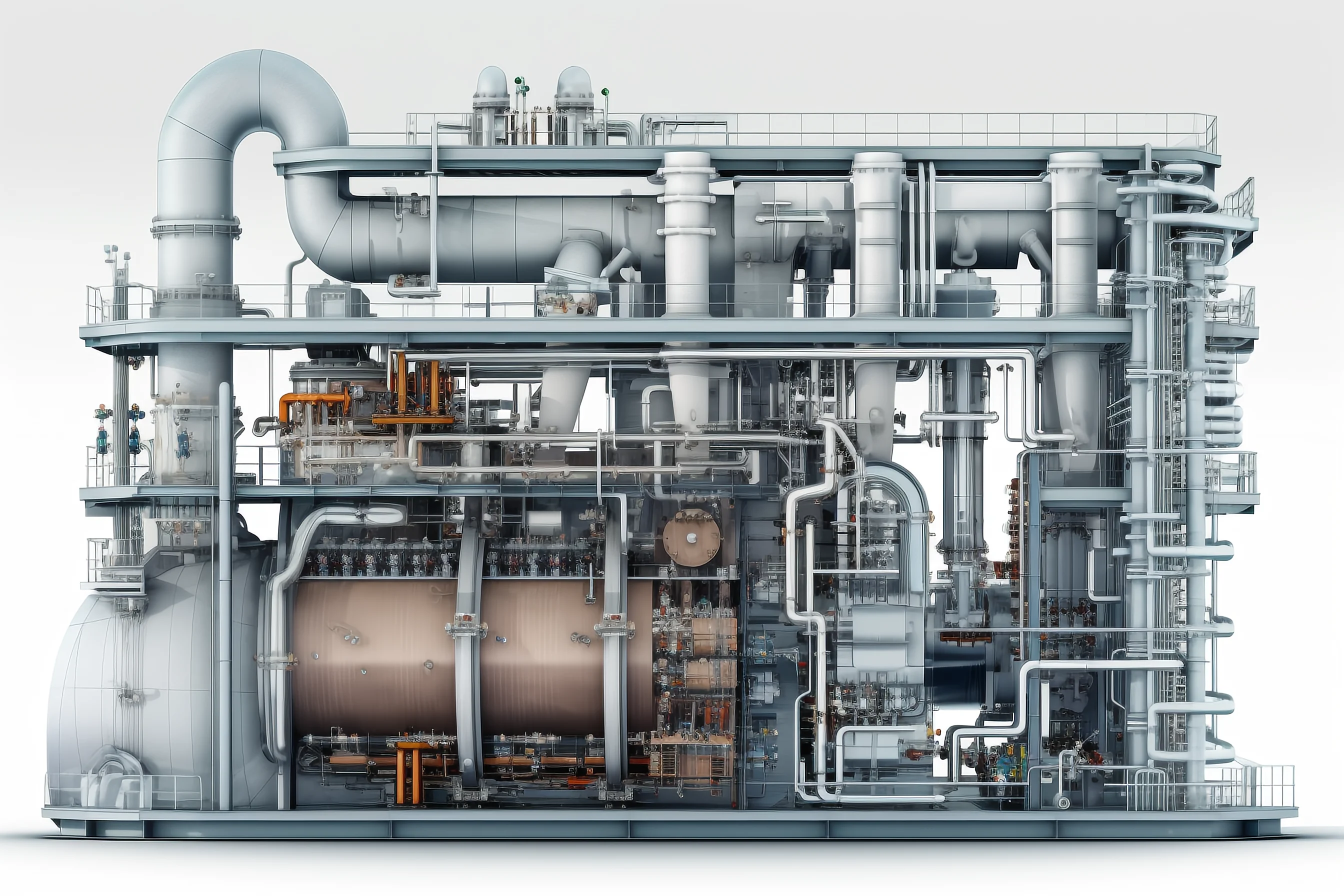

In an industry where safety, scalability, and operational efficiency are non-negotiable, the chemical processing sector increasingly turns to skid-mounted units as a strategic solution. These compact, pre-assembled, and fully integrated systems offer a flexible alternative to traditional field-constructed plants, enabling rapid deployment and reduced risk.

At the heart of this transformation is Chem-Unit, a pioneering company specializing in the research, design, manufacturing, and technical service of skid-mounted pilot plants, intermediate-scale units, production systems, and robotic laboratory equipment. With its deep understanding of chemical process requirements, Chem-Unit is helping companies of all sizes innovate safely and efficiently.

What Are Skid-Mounted Units?

A skid-mounted unit is a modular process system constructed on a steel frame or "skid," allowing the entire unit to be moved as a single piece. These systems are pre-engineered, factory-tested, and shipped ready for installation—minimizing on-site construction and startup time.

Skid systems are particularly well-suited for chemical processes that demand tight control, modularity, and scalability, such as catalyst development, solvent recovery, polymer synthesis, or gas–liquid reactions.

Key Features and Advantages

1. Compact, Modular Design

Skid-mounted units are designed to optimize space. Whether for R&D, pilot testing, or full-scale production, their compact footprint allows deployment even in space-constrained facilities. This modular approach also enables easy scaling and reconfiguration as process requirements evolve.

2. Pre-Engineering & Factory Testing

Each unit is pre-engineered and assembled in a controlled environment, ensuring consistent quality, faster build times, and reduced exposure to environmental variables. Factory acceptance testing (FAT) verifies performance and safety before delivery.

3. Plug-and-Play Installation

Once delivered, Chem-Unit’s skid systems require only basic utility connections (power, water, feedstock) before being fully operational. This drastically reduces site labor, commissioning time, and potential delays.

4. Integrated Automation & Control

Most Chem-Unit systems come with intelligent control panels, real-time data logging, and remote monitoring capabilities. Integration with DCS/SCADA systems allows full process control from a central location, enhancing operator safety and production consistency.

5. Safety & Compliance

Safety is paramount in chemical processing. Skid-mounted units are designed to meet international safety and environmental standards, including explosion-proof enclosures, emergency shutdown systems, and comprehensive alarm protocols.

6. Customization & Flexibility

Chem-Unit provides tailored solutions that match specific process requirements—whether high-pressure hydrogenation or low-temperature crystallization. Modular add-ons like distillation columns, reactors, or filtration systems can be integrated seamlessly.

Applications Across the Chemical Industry

Chem-Unit’s skid-mounted systems serve a wide range of sectors, including:

Petrochemicals & Refining – Pilot and small-batch systems for catalyst testing or feedstock conversion.

Pharmaceuticals & Fine Chemicals – GMP-compliant modular labs for synthesis and formulation.

New Materials Development – Skids used in developing battery materials, polymers, and specialty coatings.

Environmental & Green Chemistry – Systems for waste recovery, carbon capture, and bio-based reactions.

Academic & Research Institutions – Educational and experimental skids for hands-on training and advanced research.

Chem-Unit: Engineering Excellence in Skid Technology

As a trusted provider of integrated chemical processing solutions, Chem-Unit combines engineering rigor with innovative thinking. The company is also at the cutting edge of laboratory automation, offering robotic systems that enable safe, precise, and repeatable experiments—especially valuable for hazardous or high-throughput workflows.

With an emphasis on digitalization, modularity, and safety, Chem-Unit’s offerings bridge the gap between laboratory-scale experimentation and industrial-scale production.

Highlights of Chem-Unit’s Capabilities:

Full lifecycle services: design, engineering, assembly, testing, commissioning, and support

Extensive experience in multiphase reaction engineering and heat/mass transfer processes

Advanced simulation tools for flow, thermodynamics, and automation logic

Rapid prototyping and custom manufacturing for unique research or commercial needs

Global support network for installation, training, and after-sales service

Final Thoughts

Skid-mounted units are redefining how the chemical industry designs and deploys process systems. Their speed, safety, and flexibility make them indispensable for companies focused on innovation and operational efficiency.

With a deep-rooted expertise in both chemical engineering and automation, Chem-Unit stands as a leading force in delivering reliable, scalable, and future-ready skid-mounted systems. Whether you are piloting a new chemical process or scaling up for commercial production, Chem-Unit provides the tools and technical support to help you succeed—safely, efficiently, and intelligently.

Overview of Skid-Mounted Units in the Oil, Gas, and Chemical Industries

en.chem-unit.com

Overview of Skid-Mounted Units in the Oil, Gas, and Chemical Industries -

AuthorPosts

- You must be logged in to reply to this topic.