- This topic is empty.

-

AuthorPosts

-

28/03/2025 at 15:31 #82086

Precision magnetic scale linear encoders play a crucial role in modern industrial applications, offering high accuracy, reliability, and resistance to harsh environments. These encoders are integral to automation, robotics, CNC machinery, and other advanced manufacturing processes, where precise linear position measurement is essential. In this blog post, as a high performance linear encoder manufacturer, ENX Enxiao will share the industrial applications of precision magnetic scale linear encoder for sale.

Understanding Precision Magnetic Scale Linear Encoder

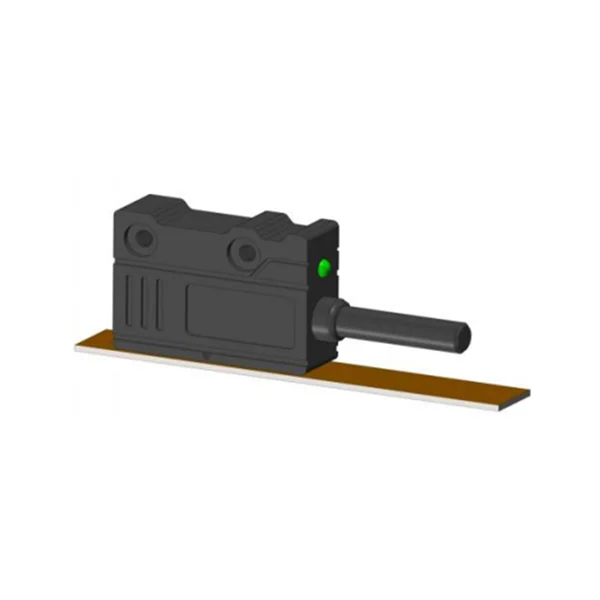

Magnetic scale linear encoders utilize magnetic principles to provide highly accurate linear displacement measurements. These encoders consist of two primary components:

1. Magnetic Scale: A stationary component embedded with a series of alternating magnetic poles (north and south) at regular intervals.

2. Readhead (Sensor): A moving component equipped with magnetic field sensors that detect changes in the magnetic pattern and convert them into electrical signals.

The readhead interprets the encoded magnetic pattern and processes the data to determine precise positional information. Some advanced encoders use additional signal processing to enhance resolution and compensate for environmental influences.

Key Advantages of Precision Magnetic Scale Linear Encoder

– High Durability: Unlike optical encoders, magnetic encoders are immune to dust, oil, and other contaminants, making them ideal for harsh industrial environments.

– Resistant to Shock and Vibration: The non-contact nature and robust construction of magnetic encoders allow them to withstand mechanical stress.

– Extended Temperature Range: Magnetic encoders operate efficiently in extreme temperatures, ranging from -40°C to over 100°C.

– Compact and Lightweight: They provide high precision without adding significant weight to the system, which is beneficial for compact and mobile machinery.

– Absolute and Incremental Encoding: They support both absolute and incremental measurement configurations, catering to different industrial needs.

Industrial Applications of Magnetic Scale Linear Encoder

1. CNC Machine Tools

Computer Numerical Control (CNC) machines require highly accurate positioning for cutting, milling, and drilling operations. Magnetic scale linear encoders provide precise feedback on the tool's position, ensuring:

– Enhanced machining accuracy

– Reduced material waste

– Improved repeatability and efficiency

2. Robotics and Automation

Industrial robots rely on precise motion control to perform complex tasks such as assembly, welding, and material handling. Magnetic encoders enable:

– Precise robotic arm positioning

– High-speed automation with minimal errors

– Reliable operation in challenging environments

3. Semiconductor Manufacturing

Semiconductor fabrication involves sub-micron accuracy, necessitating high-precision position feedback systems. Magnetic scale encoders contribute to:

– Ultra-precise wafer positioning

– Alignment in photolithography systems

– Enhanced efficiency in high-speed chip production

4. Medical Equipment

In medical imaging and diagnostic devices such as MRI scanners and CT machines, precision and stability are critical. Magnetic encoders ensure:

– Accurate positioning of scanning components

– Reduced mechanical interference

– Improved reliability in diagnostic procedures

5. Industrial Metrology

Quality control and inspection systems in manufacturing require high-resolution position measurement. Magnetic encoders facilitate:

– Precise coordinate measuring machine (CMM) operations

– High-accuracy dimensional inspection

– Automated defect detection

6. Textile and Printing Machinery

In textile production and high-speed printing, accurate movement control is necessary for quality assurance. Magnetic encoders enable:

– Precision fabric and material handling

– Synchronized motion in printing heads

– Error-free high-speed operations

7. Packaging and Material Handling

Automated packaging and conveyor systems require real-time position feedback to ensure efficient operations. Magnetic encoders offer:

– Consistent product positioning

– High-speed sorting and packaging

– Reduced downtime and maintenance

Conclusion

Precision magnetic linear encoders provide accurate, reliable and durable position measurement solutions for industrial automation. Their versatility in applications ranging from CNC machining to semiconductor manufacturing highlights their importance in modern industry. As technology advances, magnetic encoders will continue to evolve, offering even greater precision and functionality for the next generation of industrial automation systems.

http://www.enxsensors.com

ENX Enxiao -

AuthorPosts

- You must be logged in to reply to this topic.