- This topic is empty.

-

AuthorPosts

-

22/09/2025 at 17:20 #83360

Titanium anode tanks have gained significant recognition in the industrial field for their ability to withstand aggressive chemical environments and deliver stable performance over extended operational periods. These tanks are designed to serve as durable, non-reactive containers equipped with titanium-based anodes that promote efficient electrochemical reactions while minimizing material degradation.

Timonic, a company committed to the production equipment of new energy lithium battery materials, integrates titanium anode tanks as a crucial part of its equipment solutions. Through extensive research, precision engineering, and advanced material selection, Timonic provides industries with reliable systems that contribute to efficient processing and long-term operational stability.

Characteristics of Titanium as a Material for Anode Tanks

Titanium is widely recognized for its unique combination of strength, low density, and exceptional resistance to a wide range of corrosive substances. When used in anode tanks, titanium exhibits several important properties:

Outstanding resistance to acids, chlorides, and alkaline solutions.

Formation of a stable oxide layer that protects against oxidation.

High tensile strength with a lightweight structure.

Compatibility with electrochemical processes across diverse industrial sectors.

Timonic leverages high-grade titanium materials and precise fabrication techniques to ensure the tanks deliver optimal performance even under demanding conditions.

Role of Titanium Anode Tanks in Corrosion Control

Corrosion is one of the most significant challenges in industrial processing systems, leading to structural damage, product contamination, and frequent maintenance requirements. Titanium anode tanks address this issue by providing a chemically inert environment that minimizes metal dissolution and surface degradation.

The natural passivation layer on titanium prevents direct interaction between the tank’s structural material and aggressive media, reducing the risk of corrosion-induced failures. Timonic incorporates specialized surface treatments and anode designs to further enhance this protective capability.

Contribution to Electrochemical Efficiency

Beyond corrosion resistance, titanium anode tanks play a vital role in enhancing electrochemical process efficiency. Their ability to maintain stable anode potential and uniform current distribution leads to:

Consistent reaction rates within the tank.

Reduced energy losses during operation.

Improved product yield and quality control.

Timonic develops its titanium anode tanks with optimized electrode configurations and current pathways to ensure consistent output and reduced operational disruptions.

Applications in Lithium Battery Material Production

One of the key industrial sectors utilizing titanium anode tanks is the production of lithium battery materials. The processes involved in lithium battery cathode and anode material preparation often include chemical baths, electrochemical treatments, and controlled environmental conditions where corrosion resistance is paramount.

Timonic integrates these tanks into its production equipment for new energy lithium battery materials, enabling stable operation during leaching, electroplating, and other related manufacturing stages.

Use in Chemical Processing and Surface Treatment

Titanium anode tanks are also prevalent in the broader chemical processing and surface finishing industries. They are employed in plating lines, anodizing systems, and chemical storage units that handle acids, alkalis, and mixed electrolytes.

Timonic supplies customizable tank systems that align with specific process requirements, ensuring reliable chemical resistance and high processing accuracy.

Importance in Environmental and Water Treatment Systems

In environmental treatment sectors, titanium anode tanks assist in processes such as wastewater treatment, electrochemical purification, and industrial effluent neutralization. Their corrosion-resistant nature ensures consistent performance in applications involving strong oxidizing agents and variable pH conditions.

Timonic offers engineering expertise to incorporate these tanks into treatment systems, facilitating efficient resource utilization and long service life.

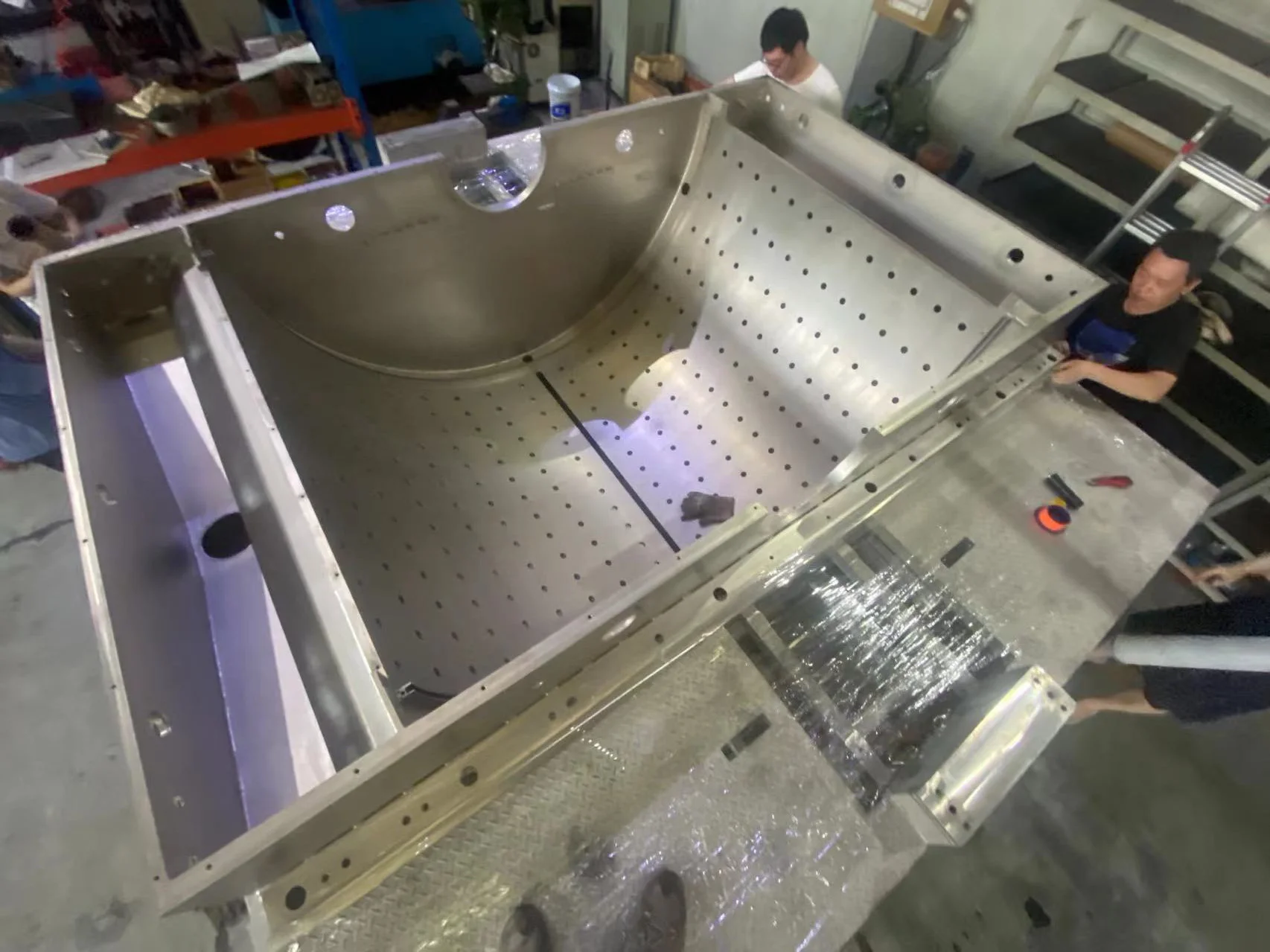

Design and Manufacturing Practices

The quality and durability of a titanium anode tank largely depend on precise design and controlled manufacturing practices. Key aspects include:

Selection of the appropriate titanium grade for the intended application.

Fabrication techniques such as precision welding and seamless forming.

Integration of high-performance anodes tailored to process specifications.

Rigorous quality inspection and performance testing.

Timonic employs stringent production standards, advanced welding technologies, and automated inspection systems to ensure that each titanium anode tank meets the highest industrial benchmarks.

Maintenance and Operational Stability

Proper maintenance of titanium anode tanks is essential to retain their performance characteristics over prolonged operational periods. This involves periodic inspection of the oxide layer, monitoring of anode conditions, and ensuring electrolyte composition remains within designated parameters.

Timonic provides guidance and technical support to clients, assisting them in establishing maintenance protocols that minimize downtime and extend equipment life cycles.

Sustainability and Resource Optimization

The integration of titanium anode tanks contributes to sustainable industrial practices by reducing material wastage, extending service intervals, and improving resource utilization rates. Their long operational life reduces the frequency of replacements, while their inert nature minimizes contamination risks.

Timonic aligns its production equipment with resource-efficient strategies, focusing on eco-friendly manufacturing processes and durable system designs.

Timonic’s Expertise in Titanium Anode Tank Integration

As a company dedicated to the production equipment of new energy lithium battery materials, Timonic combines extensive industry knowledge with advanced engineering capabilities. Its expertise encompasses:

Custom-designed titanium anode tanks for specific industrial processes.

Integration of tanks with automated control systems.

Provision of comprehensive technical support and after-sales service.

Ongoing research into material optimization and production techniques.

Through this holistic approach, Timonic ensures that its equipment solutions deliver reliable performance and meet rigorous industrial requirements.

Conclusion

Titanium anode tanks serve as a cornerstone of industrial systems where corrosion resistance and electrochemical efficiency are critical. Their use spans lithium battery material production, chemical processing, environmental treatment, and surface finishing industries.

Timonic, with its strong foundation in new energy lithium battery equipment production, continues to provide high-quality titanium anode tank solutions that enable stable, efficient, and durable industrial operations.

Electrodeposited Copper Foil Titanium Anode Tanks: Key Applications in Modern Manufacturing

http://www.timonic.com.cn

Timonic -

AuthorPosts

- You must be logged in to reply to this topic.