- This topic is empty.

-

AuthorPosts

-

16/09/2025 at 15:49 #83263

In the rapidly evolving landscape of modern manufacturing, electrodeposited copper foil has become an essential material, especially within the energy storage and electronics industries. At the heart of this production process lie titanium anode tanks, critical components that enable high-quality copper foil electrodeposition. With the rise of new energy technologies, particularly lithium-ion batteries, the demand for advanced manufacturing equipment continues to grow. Companies like Timonic, a leader in the production equipment for new energy lithium battery materials, are pioneering solutions that set new standards in efficiency and precision.

Understanding the Role of Titanium Anode Tanks

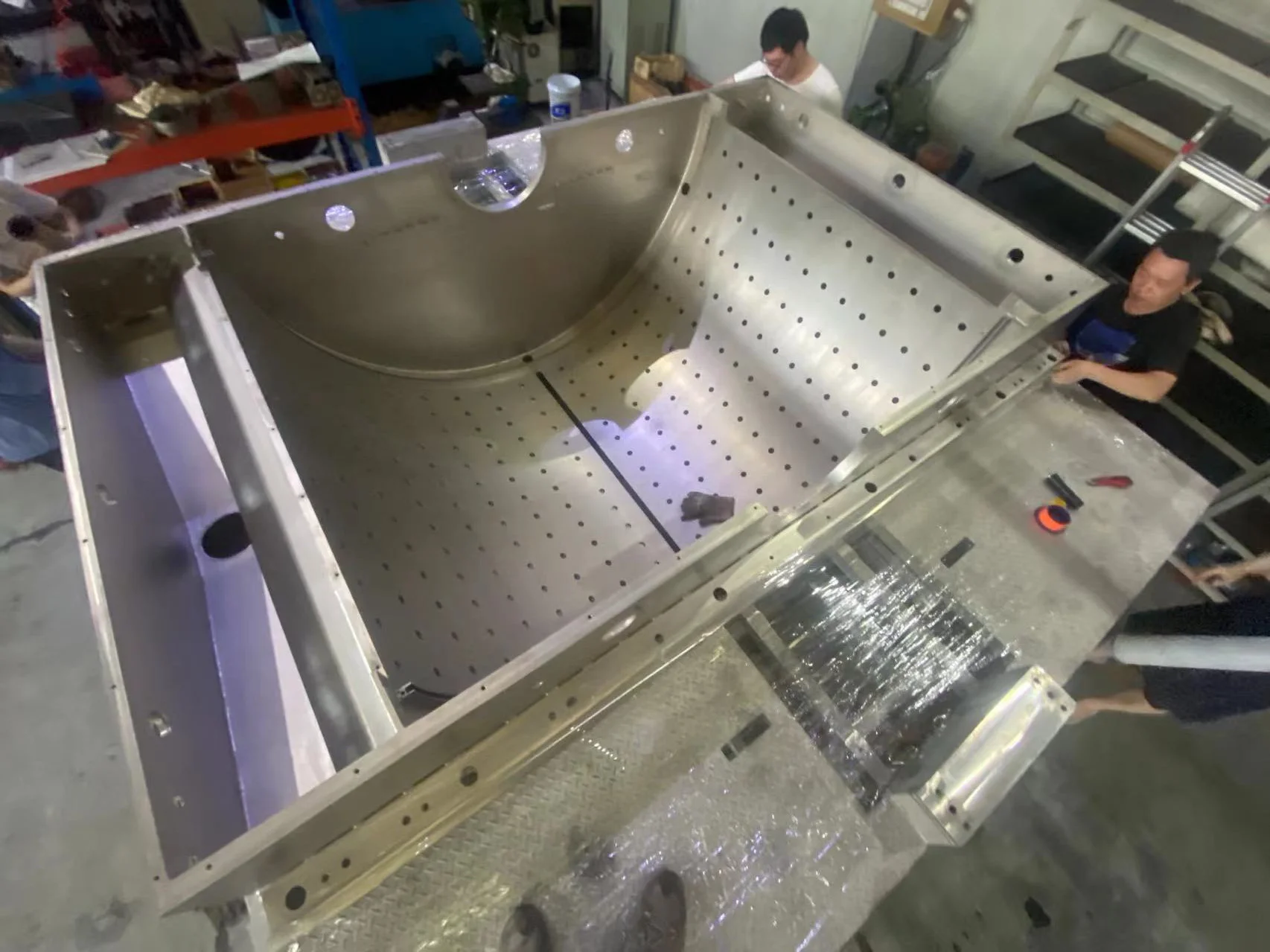

Titanium anode tanks are specialized containers used in the electrodeposition process to produce high-purity copper foil. Their exceptional corrosion resistance, mechanical strength, and stability in acidic environments make titanium the preferred material for such applications. In these tanks, copper ions are deposited onto a rotating drum or cathode, forming an ultra-thin and uniform foil that is later processed for use in various industries.

The choice of titanium not only extends the service life of the tanks but also ensures consistent production quality by minimizing contamination during the electrochemical process.

Importance in the Lithium Battery Industry

One of the most prominent applications of electrodeposited copper foil is in lithium-ion battery manufacturing. As a crucial component of the anode current collector, copper foil directly influences the performance, efficiency, and longevity of batteries. Titanium anode tanks provide the stable and reliable platform necessary for creating copper foils with high conductivity, low surface roughness, and excellent adhesion properties.

Timonic has been actively involved in developing cutting-edge production equipment that supports large-scale and high-precision manufacturing of copper foils for next-generation batteries, including those used in electric vehicles, energy storage systems, and consumer electronics.

Applications Beyond Energy Storage

While the lithium battery sector represents a major share of demand, electrodeposited copper foil and its titanium anode tanks also serve other industries:

Printed Circuit Boards (PCBs): Essential for producing high-quality copper layers in electronics manufacturing.

Telecommunication Equipment: Supports the growing need for reliable, high-performance conductive materials.

Automotive Electronics: Ensures durable and efficient electronic systems in modern vehicles.

Flexible Electronics: Enables the creation of lightweight, bendable circuits for wearable devices and smart technologies.

The versatility of titanium anode tanks makes them an integral part of the broader electronic materials supply chain.

Advantages of Using Titanium in Anode Tank Design

The unique properties of titanium offer several key benefits in electrodeposited copper foil production:

Outstanding resistance to acid and chloride corrosion, ensuring long-term operational stability.

Excellent strength-to-weight ratio, making it both durable and manageable for industrial-scale systems.

Minimal contamination risk, leading to higher-quality copper foil output.

Compatibility with automated production lines, improving efficiency and reducing downtime.

These advantages have led to widespread adoption in both established and emerging markets.

How Timonic Advances Manufacturing Innovation

As a company committed to new energy lithium battery materials production equipment, Timonic continues to invest in research, innovation, and precision engineering. By integrating advanced automation, process optimization, and environmentally sustainable practices, Timonic delivers titanium anode tank solutions that align with the fast-changing needs of the global manufacturing industry.

Through strategic partnerships, continuous product refinement, and a focus on quality, Timonic plays a pivotal role in enabling manufacturers to meet the growing demand for high-performance copper foil.

Key Considerations for Manufacturers

When selecting titanium anode tanks for electrodeposited copper foil production, manufacturers should evaluate:

Required thickness and uniformity of copper foil.

Chemical composition and operational conditions of the electrolyte.

Long-term cost-effectiveness, including maintenance and replacement cycles.

Supplier reputation and after-sales technical support.

Timonic’s expertise ensures tailored solutions that address these considerations, helping businesses scale efficiently while maintaining exceptional product quality.

Conclusion

Titanium anode tanks have become an essential enabler in the production of electrodeposited copper foil, driving innovation across multiple manufacturing sectors. From high-capacity lithium-ion batteries to advanced electronics, their applications continue to expand as industries demand higher performance and sustainability. With industry leaders Timonic at the forefront, the future of electrodeposited copper foil production promises to be more efficient, reliable, and technologically advanced.

Troubleshooting and Maintenance Guide for Power Conducting Arms

http://www.timonic.com.cn

Timonic -

AuthorPosts

- You must be logged in to reply to this topic.