- This topic is empty.

-

AuthorPosts

-

26/03/2025 at 17:43 #82058

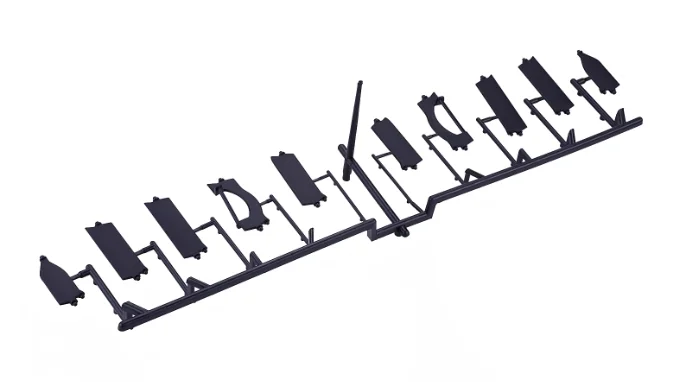

Automotive interiors have become increasingly complex, requiring high-precision components with superior aesthetics and functionality. One of the most critical aspects of manufacturing these components is injection molding, a process that enables the mass production of high-quality plastic parts. To achieve excellent results, the design of the injection mold is paramount. As a high precision plastic injection mold components manufacturer, Xuzhong specialize in providing automotive interior injection mold design customization services.

Understanding Automotive Interior Injection Mold Design

Injection mold design for automotive interiors involves meticulous planning and engineering. The molds must be able to produce components that meet stringent industry standards, ensuring dimensional accuracy, durability, and aesthetic appeal.

Key Considerations in Automotive Interior Injection Mold Design

1. Material Selection

– The choice of plastic material significantly impacts the mold design. Common materials include polypropylene (PP), acrylonitrile butadiene styrene (ABS), polycarbonate (PC), and thermoplastic elastomers (TPEs).

– Consideration must be given to mechanical properties such as strength, flexibility, impact resistance, and heat resistance.

2. Mold Cavity and Core Design

– Molds typically consist of two primary components: the cavity (female part) and the core (male part).

– The cavity and core must be precisely machined to achieve the desired shape and texture of the final part.

3. Cooling System Optimization

– Efficient cooling is crucial to minimizing cycle times and avoiding defects such as warping and sink marks.

– Common cooling methods include conformal cooling, baffles, and heat pipes.

4. Gate and Runner System

– The location and type of gating system influence material flow and minimize defects.

– Common gate types include pin gates, edge gates, and hot runner systems.

5. Ejection System Design

– Ensuring proper part ejection without damage is essential.

– Ejector pins, sleeves, and stripper plates must be strategically placed to avoid visible marks on the finished part.

6. Surface Finish and Texturing

– Automotive interiors require high-quality finishes to match aesthetic and tactile expectations.

– Mold texturing can be achieved through chemical etching or laser engraving to provide grain patterns.

Custom Services in Automotive Interior Injection Mold

Customization in injection molding is vital to meeting unique automotive interior design requirements. Custom services encompass mold modifications, prototyping, and precision engineering to enhance performance and aesthetics.

Prototyping and Pre-Production Validation

– Before full-scale production, prototypes help evaluate mold performance.

– Techniques such as 3D printing and soft tooling are used for rapid prototyping.

Mold Flow Analysis

– Advanced simulation software (e.g., Moldflow, SolidWorks Plastics) helps predict material flow, cooling efficiency, and potential defects.

– This analysis optimizes mold design before manufacturing, reducing errors and costs.

Precision Tooling and Engineering

– CNC machining, EDM (Electrical Discharge Machining), and high-precision grinding ensure the mold's dimensional accuracy.

– High-quality steel, such as H13 or P20, is often used for durability and longevity.

Multi-Cavity and Family Molds

– To improve efficiency, multi-cavity molds can produce multiple parts simultaneously.

– Family molds allow different components to be molded in the same cycle, optimizing production.

Conclusion

Automotive interior injection mold design is a highly specialized field requiring precision engineering and customization. By leveraging advanced mold design principles, prototyping, and custom services, manufacturers can achieve superior quality and efficiency in production. As the industry evolves, innovations in mold technology will continue to drive improvements in performance, sustainability, and design flexibility.

http://www.xuzhongmold.com

Xuzhong -

AuthorPosts

- You must be logged in to reply to this topic.